Application

Permanent magnet applications in general can be divided into four categories, as follows:

CATEGORY 1

Applications that make use of the tractive and/or repelling force of the magnet, i.e., the attraction between a magnet and a soft magnetic material, such as a piece of iron or steel, or the attraction or repulsion between two magnets, is used to do mechanical work. The following applications are in this category:

- Magnetic separators, magnetic holding devices, such as magnetic latches.

- Magnetic torque drives

- Magnetic bearing devices

CATEGORY 2

Applications that make use of the magnetic field of the magnet to convert mechanical energy to electrical energy. Some of these applications are:

- Magnetos

- Generators and alternators

- Eddy current brakes (used widely for watt-hour meter damping). (This application could be listed under electrical to mechanical energy conversion; but as mechanical energy is used to create the eddy currents, it will be discussed with this group.)

CATEGORY 3

Applications that make use of the magnetic field of the magnet to convert electrical energy to mechanical energy. Some of these applications are:

- Motors

- Meters

- Loudspeakers

- Relays

- Actuators, linear, and rotational

CATEGORY 4

Applications that use the magnetic field of the magnet to direct, shape and control electron or ion beams. Some of these applications follow:

- Magnetic focused cathode-ray tubes

- Traveling Wave Tubes

- Magnetrons, BWO, Klystrons

- Ion Pumps

- Cyclotrons

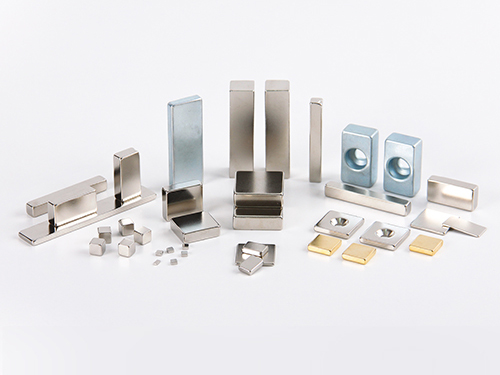

Matching Dailymag Magnetics Products to Applications

The purpose of a permanent magnet is to produce flux in the working gap of a device. Obviously all permanent magnetic material will produce flux, but depending upon the working application, certain material types, grades and shapes will be more efficient than others. The following is a breakdown by product line applications that are most suitable for a material?s characteristics:

Key reasons for using Neodymium are:

High energy for size

More economical than Samarium Cobalt

Good in ambient temperature situations

Very high Hc and Hci output

On the negative side of neodymium are relatively high price, corrosion that can result in loss of energy, and temperature coefficient of .13%/ degree centigrade.

Some of the ever-growing list of uses are:

Computer rigid disc drives

Linear actuators

Hammerbank printers

Speakers

Microphone assemblies

Magnetic separators

DC Motors & Automotive starters

Servo Motors

While being quite expensive, samarium cobalt magnets are:

High Hc and Hci

High Bhmax

Very good temperature stability

Powerful for size

On the negative side, samarium cobalt is price sensitive due to cobalt supply and demand.

Samarium Cobalt is used in these general applications:

Traveling wave tubes

Computer rigid disc drives

D.C. Motors (where temperature stability is vital, such as, Military use-satellite systems,

small military motors) sensors, growing automotive applications and linear actuators.

Key attributes of ceramic magnets & Arnold?s products are:

Economical High Hc and Hci compared to Alnico

On the negative side, ceramics are good for simple shapes only, very fragile, require expensive tooling, and temperature sensitive (0.2%?C.)

Generally ceramic magnets are used in:

DC permanent magnet motors used in the automobile industry for blowers, window lifts, windshield wipers, etc. (NOTE: Many of the motors come from outside sources not tied directly to the auto company itself). Separators to remove ferrous materials from liquid powder and bulk commodities.

Magnetic Resonate Imaging, MRI

Magnetos used on lawnmowers, garden tractors and outboard motors.

DC brushless motors with controllers for speed and direction.

The key attributes of Cast Alnico are:

- Mechanically strong

- Cast to a variety of shapes

- Very temperature stable

- Can change magnetic orientation

- High Br and Bhmax characteristics compared to ceramic materials.

The key attributes of Sintered Alnico are:

- Mechanically strongest of the Alnicos

- Close tolerance pressing/typically minimum grinding

NOTE: Both cast and sintered Alnico have low Hc when compared to ceramic or rare earth materials.

eneral applications for both cast and sintered Alnico are:

- Electron tubes, radar, traveling wave tubes.

- Separators, holding magnets, coin acceptors, clutches and bearings.

- Magnetos, motors, generators, meters, instruments, controls, relays, watt-hour meters (bearings and dampeners).

- Communications, receivers, telephones, microphones, bell ringers, musical instruments (guitar pickups).

- Automotive sensors, loudspeakers, cow magnets, distributors.

What are the uses of the magnets in your daily use ?

- Locate metal studs in a wall Seal off air-conditioning vents to improve home heating by placing vinyl-coated sheets over the steel register faces

- Hang Polaroid of projects-in-process on the lip of a metal shelf above the workbench

- Collect nails from a porch repair job that have fallen in the grass

- Prevent corrosion inside your water heater; a magnet placed on the freshwater intake pipe catches damaging metallic calcium particles before they can get inside

- Pin blueprints onto the side or hood of the truck

- Create a bulletin board without the use of tacks, tape, or hooks on walls coated with magnetized paint containing metals

- Protect a tractor engine: Ceramic magnets placed in the oil pan will attract steel bits that get into the oil from grinding pistons

- Fasten steel framing squares to the outside of toolboxes for quick access by gluing magnets to the box sides

- Clean up metal shavings that have fallen from the bench grinder onto the workshop floor