Popularization of magnetic knowledge-15 concepts explaination related to magnetic materials

1. Magnetism

Experiments show that any substance can be magnetized more or less in an external magnetic field, but the degree of magnetization is different. According to the characteristics of the material in the external magnetic field, the material can be divided into five categories: paramagnetic material, diamagnetic material, ferromagnetic material, ferrimagnetic material, and antiferromagnetic material. We call paramagnetic materials and diamagnetic materials weakly magnetic materials, and call ferromagnetic materials and ferrimagnetic materials strong magnetic materials.

2. Magnetic materials

Soft magnetic material: The maximum magnetization can be achieved with the smallest external magnetic field. It is a magnetic material with low coercivity and high permeability. Soft magnetic materials are easy to magnetize and also easy to demagnetize. For example: soft ferrite, amorphous nanocrystalline alloy.

Hard magnetic materials: also called permanent magnetic materials, which refer to materials that are difficult to magnetize and are difficult to demagnetize once magnetized. Its main feature is high coercivity, including rare earth permanent magnetic materials, metal permanent magnetic materials and permanent ferrites .

Functional magnetic materials: mainly magnetostrictive materials, magnetic recording materials, magnetoresistance materials, magnetic bubble materials, magneto-optical materials, and magnetic thin film materials.

3. NdFeB permanent magnet material

The sintered NdFeB permanent magnet material adopts powder metallurgy technology. The smelted alloy is made into powder and pressed in a magnetic field to form a compact. The compact is sintered in an inert gas or vacuum to achieve densification, in order to improve the coercivity of the magnet , Usually requires aging heat treatment, and then after processing and surface treatment to obtain the finished product.

Bonded neodymium iron boron is made of permanent magnet powder mixed with good windability rubber or hard and light plastic, rubber and other bonding materials, and directly formed into permanent magnet parts of various shapes according to user requirements.

Hot-pressed NdFeB can achieve magnetic properties similar to sintered NdFeB without adding heavy rare earth elements, with high density, high orientation, good corrosion resistance, high coercivity and near-final molding, etc. Advantages, but the mechanical performance is not good and the processing cost is higher due to patent monopoly.

4. Remanence Br

It refers to the magnetic induction intensity of a sintered neodymium iron boron magnet when a magnet is magnetized by an external magnetic field in a closed circuit environment until the technology is saturated and then the external magnetic field is cancelled. In layman's terms, it can be temporarily understood as the magnetic force of the magnet after magnetization. The unit is Tesla (T) and Gauss (Gs), 1Gs=0.0001T.

5. Coercivity Hcb

When the magnet is magnetized in the reverse direction, the value of the reverse magnetic field strength required to reduce the magnetic induction intensity to zero is called the magnetic coercive force. However, the magnetization of the magnet is not zero at this time, but the applied reverse magnetic field and the magnetization of the magnet cancel each other out. At this time, if the external magnetic field is removed, the magnet still has certain magnetic properties. 1A/m=(4π/1000)Oe, 1 Oe=(1000/4π) A/m.

6. Intrinsic coercivity Hcj

The strength of the reverse magnetic field required to reduce the magnetization of the magnet to zero is called the intrinsic coercivity. The classification of magnetic grades is based on their intrinsic coercivity. Low coercivity N, medium coercivity M, high coercivity H, ultra-high coercivity UH, extremely high coercivity EH, highest coercivity TH.

7. Maximum magnetic energy product (BH)max

It represents the magnetic energy density established by the space between the two magnetic poles of the magnet, that is, the magnetostatic energy per unit volume of the air gap, which is the maximum value of the product of B and H, and its size directly indicates the performance of the magnet. Under the same conditions, that is, the same size, the same number of poles and the same magnetizing voltage, the magnetic parts with high magnetic energy product can obtain higher surface magnetism, but at the same (BH)max value, the levels of Br and Hcj It has the following effects on magnetization:

High Br, low Hcj: Under the same magnetizing voltage, higher surface magnetism can be obtained;

Br is low, Hcj is high: To obtain the same surface magnetism, a higher magnetizing voltage is required.

8.SI system and CGS system

The International System of Units and the Gaussian System of Units are like the difference between "meter" and "mile" in the unit of length. There is a complex conversion relationship between the International System of Units and the Gaussian System of Units.

9. Curie temperature

It is the temperature at which a magnetic material changes between a ferromagnetic body and a paramagnetic body. When the temperature is lower than the Curie temperature, the material becomes a ferromagnetic body. At this time, the magnetic field related to the material is difficult to change. When the temperature is higher than the Curie temperature, the substance becomes a paramagnetic body, and the magnetic field of the magnet can easily change with the surrounding magnetic field.

The Curie temperature represents the theoretical working temperature limit of magnetic materials. The Curie temperature of NdFeB is about 320-380 degrees Celsius. The level of the Curie point is related to the crystal structure formed by the sintering of the magnet. If the temperature reaches the Curie temperature, the molecules inside the magnet move violently and demagnetize, which is irreversible; after the magnet is demagnetized, it can be magnetized again, but the magnetic force will drop significantly, only reaching about 50% of the original.

10. Working temperature

The maximum working temperature of sintered NdFeB is much lower than its Curie temperature. The magnetic force will decrease when the temperature rises, but most of the magnetic force will recover after cooling.

The relationship between working temperature and Curie temperature: The Curie temperature is about higher, the working temperature of the magnetic material is relatively higher, and the temperature stability is better. Adding cobalt, terbium, dysprosium and other elements to the sintered neodymium iron boron raw materials can increase its Curie temperature, so high coercivity products (H, SH,...) generally contain dysprosium.

The maximum operating temperature of sintered NdFeB depends on its own magnetic properties and the selection of operating points. For the same sintered NdFeB magnet, the closer the working magnetic circuit is, the higher the maximum use temperature of the magnet and the more stable the performance of the magnet. Therefore, the maximum operating temperature of the magnet is not a certain value, but changes with the degree of closure of the magnetic circuit.

11. Magnetic field orientation

Magnetic materials are divided into two types: isotropic magnets and anisotropic magnets. Isotropic magnets have the same magnetic properties in any direction and can be attracted together at will; anisotropic magnets have different magnetic properties in different directions. The direction in which it can obtain the best magnetic properties is called the orientation direction of the magnet.

For a square sintered NdFeB magnet, only the orientation direction has the highest magnetic field strength, and the other two directions are much smaller. If the magnetic material has an orientation process in the production process, it is an anisotropic magnet. Sintered NdFeB is generally molded and pressed by magnetic field orientation, then it is anisotropic, so the orientation direction needs to be determined before production, the upcoming magnetization direction . Powder magnetic field orientation is one of the key technologies for manufacturing high-performance NdFeB. (The bonding of NdFeB has isotropic and anisotropic)

12. Magnetic

It refers to the magnetic induction intensity at a certain point on the surface of the magnet (the surface magnetism of the center and the edge of the magnet are not the same). It is the value measured by the Gauss meter contacting a certain surface of the magnet, not the overall magnetic performance of the magnet.

13. Magnetic flux

Suppose that in a uniform magnetic field with a magnetic induction intensity of B, there is a plane with an area S and perpendicular to the direction of the magnetic field. The product of the magnetic induction intensity B and the area S is called the magnetic flux passing through this plane, referred to as the magnetic flux, and the symbol "Φ" , The unit is Weber (Wb). Magnetic flux is a physical quantity that represents the distribution of the magnetic field. It is a scalar, but it has positive and negative values, which only represent its direction. Φ=B·S, when there is an angle θ between the vertical plane of S and B, Φ=B·S·cosθ.

14. Electroplating

The sintered neodymium iron boron permanent magnet material is produced by powder metallurgy technology. It is a chemically active powder material. There are tiny pores and cavities inside, which are easily corroded and oxidized in the air. Therefore, strict surface treatment must be performed before use. Electroplating is widely used as a mature metal surface treatment method.

The most commonly used coatings of neodymium iron boron strong magnets are zinc plating and nickel plating. They have obvious differences in appearance, corrosion resistance, service life, and price:

Polishing difference: nickel plating is superior to zinc plating on polishing, and the appearance is brighter. Those with high requirements on the appearance of the product generally choose nickel plating, while some magnets are not exposed, and the general zinc plating is relatively low on the appearance of the product.

Difference in corrosion resistance: Zinc is an active metal and can react with acid, so it has poor corrosion resistance; after nickel-plated surface treatment, its corrosion resistance is higher.

Difference in service life: Due to the different corrosion resistance, the service life of zinc plating is lower than that of nickel plating. The main manifestation is that the surface coating is easy to fall off after a long time of use, causing the magnet to oxidize, which affects the magnetic performance.

Hardness difference: Nickel plating is higher than zinc plating. During use, collisions can be avoided to a great extent, causing the neodymium iron boron strong magnet to appear corners and chipping.

Price difference: galvanizing is very advantageous in this respect, and the prices are arranged from low to high as galvanizing, nickel plating, epoxy resin, etc.

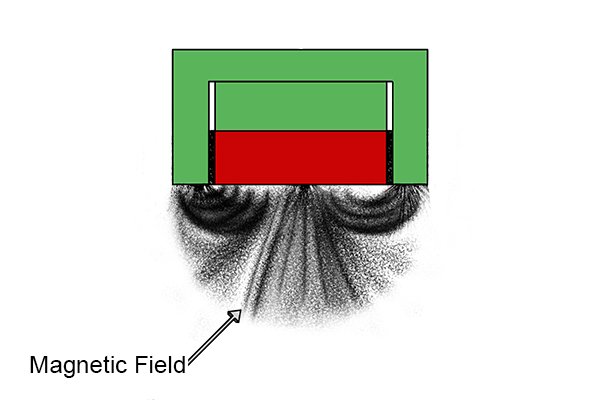

15.Single-sided magnet

Magnets have two poles, but in some working positions, single-sided magnets are needed. Therefore, one side of the magnet needs to be covered with iron sheets so that the side covered by the iron sheets is magnetically shielded. Such magnets are collectively called single-sided magnets. Or single-sided magnet. There is no real single-sided magnet.