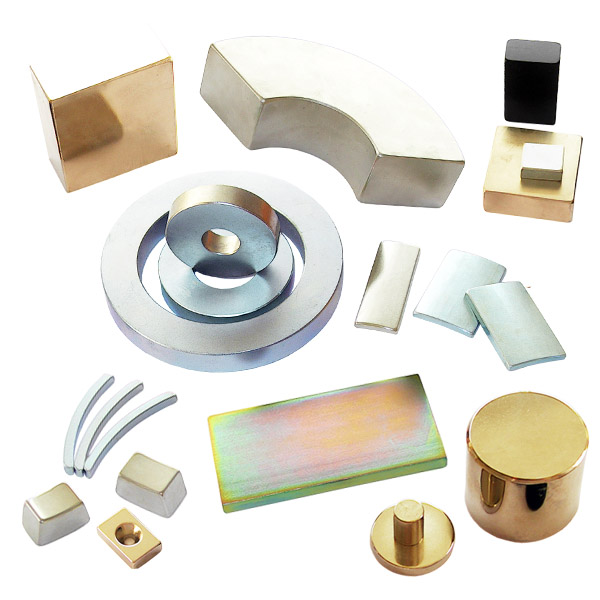

Production process of sintered NdFeB magnet-(3) Orientation forming

Magnetic field orientation forming uses the interaction of magnetic powder and external magnetic field to arrange the easy magnetization direction of powder particles to make it consistent with the final magnetization direction of the magnet. This is the most commonly used method to obtain anisotropic magnets. The powder preparation process breaks the Nd-Fe-B alloy into single crystal particles, and they are uniaxially anisotropic. Each particle has only one easy magnetic axis—the c-axis of the main phase unit cell. The powder is loosely filled into the mold, and the filling density is about 25%-30% of the actual density. Under the action of an external magnetic field above 0.8A/m, these powder particles change from multi-domain to single-domain, and rotate or move them. The easy magnetization direction is adjusted to the direction of the external magnetic field.

In industrial production, the current press forming methods are divided into two categories: one-time forming and two-time forming.

One-time forming can use a unidirectional press (the pressure is generally 50-100MPa, the compact density is 55%-60% of the solid density) or cold isostatic press (the pressure is generally 200MPa, the compact density is 60% of the solid density ).

Two-time forming can use a one-way press (the pressure is generally 20-30MPa, the compact density is 45% of the solid density) plus a cold isostatic press (the pressure is generally 200MPa, the compact density is 60% of the solid density) .

During the orientation forming process, the alloy powder basically retains the state of c-axis orientation. After the pressing is completed, the blank is demagnetized (eliminating the damage to the orientation of adjacent particles by the magnetic dipole interaction between the magnetic powder particles), and then demolded. A blank with good orientation in the easy magnetization direction can be obtained.

The pressure as high as 100 MPa will force the magnetic powder to obey the balance condition of mechanical force and magnetic force. It will inevitably cause the movement or rotation of the magnetic powder particles, which may cause the c-axis to deviate from the direction of the external magnetic field and reduce the orientation of the blank. Therefore, the magnetic field formation process is to reasonably balance the relationship between the magnetic field strength and the forming pressure on the premise of reaching the blank density, and obtain the highest degree of orientation as possible.

The degree of powder orientation is also affected by the internal friction of the powder. The impact is especially serious when the loose density is large. In actual production, organic lubricants are used to reduce internal friction, but it must be removed before the sintering reaction occurs (usually around 200°C). The lubricant is completely released to prevent oxidation or carbonization of the lubricant and reduce the performance of the magnet.

There are usually three types of forming processes in actual production:

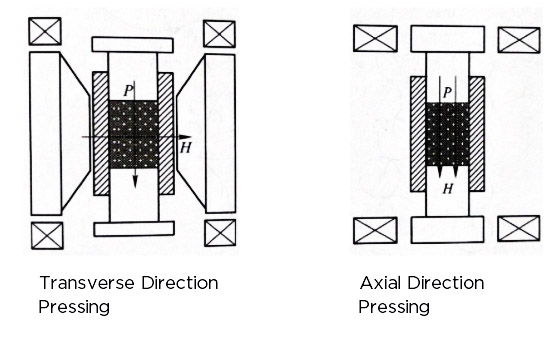

Transverse Direction Pressing, TDP

Axial Direction Pressing, ADP

Isostatic Pressing, IP (Isostatic pressing usually uses a liquid medium, and isostatic pressing with rubber as a medium is called Rubber Isostatic Pressing, RIP)

The most common pressing process is vertical pressure, as the name implies, the magnetic field direction H is perpendicular to the pressing direction P; parallel pressure means that the magnetic field direction is parallel to the forming pressure; while isostatic pressure is to apply pressure to the magnetic powder uniformly in all directions through a medium such as a liquid or a rubber mold. . In the case of the same process parameters such as magnetic powder filling, magnetic field strength, and forming pressure, the performance of the magnet obtained by the isostatic pressing method is the highest, the vertical pressing is the second, and the parallel pressing is the lowest. If the orientation degree is measured by the ratio of remanence and saturation magnetization, RIP is as high as 94%~96%, TDP is 90%~93%, and ADP is only 86%~88%, which is between the three (BH) The max can differ by 16~40kJ/m3 (2~5MGOe). This difference typically reflects the competitive relationship between mechanical pressure, magnetic dipole interaction, and internal and external friction.

Cold isostatic pressing is also often used for secondary pressing of one-way pressed blanks. In the case of limited orientation magnetic field, first use a lower pressure to obtain the appropriate degree of orientation, and then use isostatic pressing to further increase the density of the compacts. Does not destroy the existing orientation level.